SMRT to upgrade 92 trains with enhanced fault detection and air-conditioning system

SMRT will progressively upgrade 92 trains with real-time fault detection and improved air-conditioning, aiming to enhance reliability and commuter comfort. The prototype train is being tested ahead of a full rollout by the mid-2030s.

- SMRT will upgrade 92 trains with real-time monitoring, starting with one prototype.

- The enhancements aim to detect faults early and improve commuter comfort.

- Full rollout is expected by the mid-2030s across North-South and East-West lines.

SMRT will progressively upgrade 92 of its trains with a suite of enhancements designed to improve fault detection, reduce service disruptions, and enhance passenger comfort, the transport operator announced on 18 December 2025.

The upgrades, currently being trialled on a prototype C151B train, include a new air-conditioning and ventilation system and 180 additional sensors distributed across the train to monitor various operational components in real time.

According to SMRT, the upgraded systems will allow earlier detection of potential faults, which could help prevent prolonged service interruptions. The initiative is being led by STRIDES Technologies, a subsidiary of SMRT.

The system will monitor real-time variables such as cabin temperature, door function, braking systems, and the mechanical condition of bogies — the undercarriage that houses wheels and suspension systems. Alerts will be sent to a central maintenance control centre located at Bishan Depot.

Simple adjustments, such as changing air-conditioning temperatures, can be made while the train remains in service. In more serious cases, the train may be withdrawn from service or issues can be addressed after the day’s operations.

In total, the 92 trains to be upgraded include 35 fourth-generation C151A trains, 45 fifth-generation C151B trains, and 12 sixth-generation C151C trains. The upgrades are scheduled for completion by the mid-2030s.

The new systems are currently undergoing validation, and if successful, SMRT will work with the Land Transport Authority (LTA) to implement the enhancements across the fleet.

The current proof-of-concept project began with a contract signed in November 2024 between SMRT and CRRC Sifang, a Chinese rail manufacturer.

Modification work started in the first half of 2025 at CRRC Sifang’s facility in Qingdao, with initial testing conducted between August and September. The modified train cars arrived in Singapore in October 2025 and have since undergone further testing and commissioning.

The prototype train, painted in red and white to reflect the Singapore flag, is expected to begin passenger service in June 2026 on the North-South and East-West lines.

One key enhancement is the replacement of the existing air-conditioning system, which SMRT described as “ageing and unable to sustain its intended cooling capacity”. The new system uses high-efficiency components with longer operational life and a refrigerant with lower global warming potential. Sensors will monitor for filter blockages and refrigerant leaks, allowing maintenance teams to respond promptly.

Temperature sensors in the cabin will enable real-time adjustments to maintain optimal comfort.

Another notable addition is the bogie monitoring system. Currently, trains lack the capability to continuously assess the condition of bogie components while in service. The new system will track wheel wear, axle load, temperature, vibrations, and structural integrity.

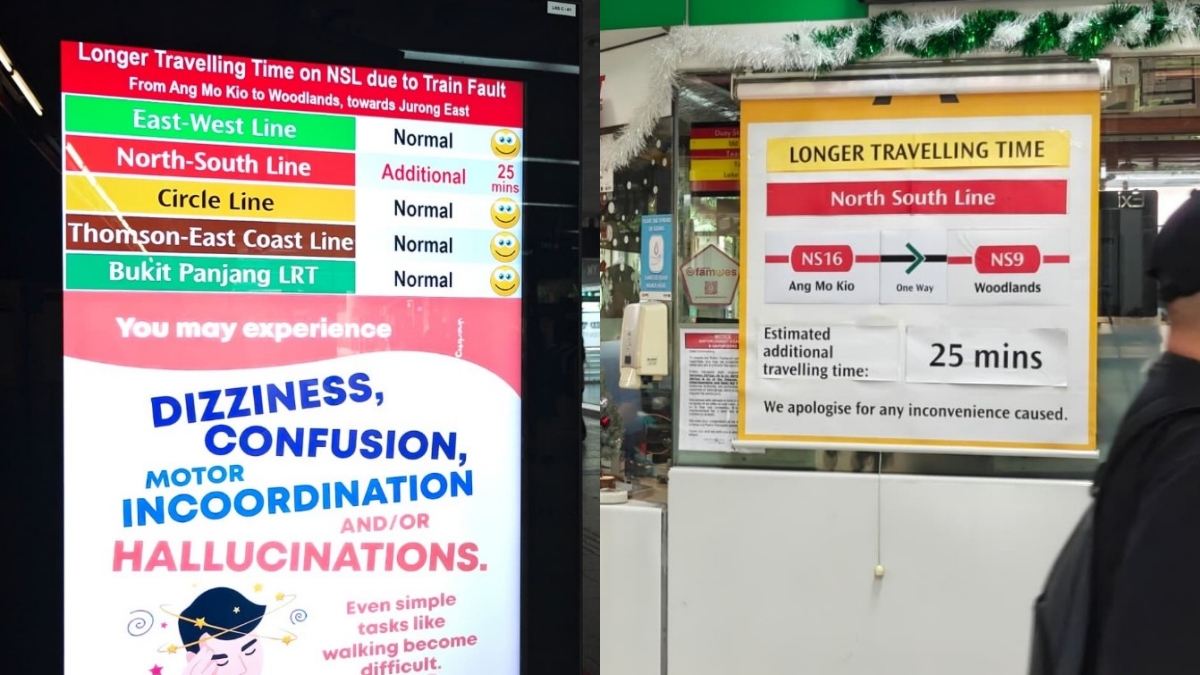

This aims to prevent costly and disruptive failures, such as a six-day disruption in September 2024 on the East-West Line caused by a defective axle box that dislodged and damaged the tracks.

Train doors will also be monitored more precisely. At present, a fault alert only identifies the affected train cabin, requiring staff to manually inspect multiple doors. The new system will pinpoint the specific faulty door, speeding up repair times.

Beyond these, other onboard components such as brakes, power systems, and air-conditioning units will also be monitored for anomalies or performance degradation.

STRIDES Technologies managing director Andy Chiang stated, “Sensors embedded in our trains enable us to detect potential issues before they become faults. These timely alerts enhance rail reliability and deliver more comfortable journeys for everyone.”

Kenneth Sim, Section Head of Frontline Maintenance at SMRT, demonstrated the use of inspection tools such as borescopes, which are used to verify issues like door roller defects. These tools will complement the new automated systems by allowing rapid visual confirmation of identified issues.

SMRT noted that this technological overhaul aligns with its long-term strategy to futureproof its operations and ensure service quality keeps pace with expanding commuter demand.

“The intent is to identify faults before they happen. This is essential for futureproofing as well as meeting growing commuter demands as the rail network expands,” the company said in a statement.

The rail operator has also invested over S$1 million in other initiatives to boost track quality and overall reliability, as part of a broader move to modernise its rail infrastructure and operations.